HomeEssentials of Metal Additive Manufacturing Short Course Training Program

Essentials of Metal Additive Manufacturing Short Course Training Program

A short course to learn the fundamentals of metal 3D printing, additive design & manufacturing from a global leader, GE Additive and Western Sydney University.

Essentials of Metal Additive Manufacturing

Course Overview

This course provides an introduction to additive manufacturing, also known as 3D printing, a process that creates a physical object from a digital design file.

Additive manufacturing enables engineers to design parts, systems and shapes once thought impossible to make.

Additive manufacturing allows for complex design geometries, making products that are lighter, stronger and more efficient, revolutionising products in many industries.

Course Details

This short course training program will be delivered online via Zoom, concluding with a face-to-face factory visit session at Kingswood.

Cohort 8: Tuesday 12-21 September, 2023

Week 1

- Tuesday 12th September: 8:00am – 12:00pm

- Wednesday 13th September: 8:00am – 12:00pm

Week 2

- Tuesday 19th September: 8:00am – 12:00pm

- Wednesday 20th September: 8:00am – 12:00pm

- Thursday 21st September: 9:00am – 1:00pm (face-to-face factory tour)

Entry Criteria: No additive manufacturing experience is necessary, the course is suitable for company owners, CEO’s/MD’s, managers, designers, technicians, tradespeople and apprentices working in the manufacturing sector.

Cost: Course fees waived for *eligible participants

Course Structure

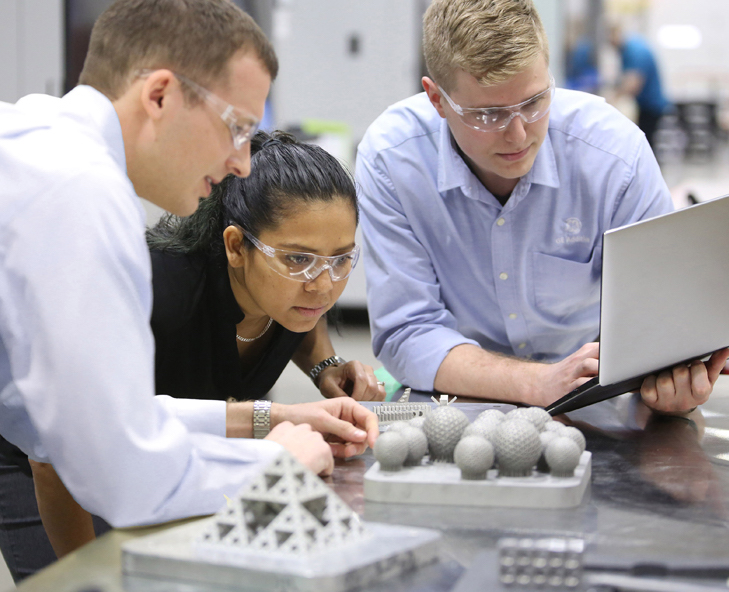

The Essentials of Metal Additive Manufacturing short training course is delivered through interactive sessions. A final, hands-on session is held at Western Sydney University’s Makerspace in Kingswood, allowing participants to put newfound knowledge into practice.

Interactive sessions on the topics below

- Introduction to Additive Manufacturing

- Design considerations for DMLM

- Design considerations for EBM

- Design considerations for Binder Jetting

- Additive materials considerations

- Understanding the qualification of additive components

- Business case development

- Investigating additive part selection

- Part identification Case Study

In-person session at WSU Advanced Manufacturing Precinct

- Visit to Western Sydney University’s Advanced Manufacturing Precinct for a hands-on experience using skills learnt throughout course.

Testimonials

‘This course exceeded my expectations. The presenters are genuine experts in their field of the kind you rarely get access to. The time commitment was about right: 5 half day over two weeks was enough to go deeply into the subject without too much extraneous material. I now feel like I am heading down the road toward advanced manufacturing with a map in my hand, armed with a much better understanding of the fundamentals’

Colin Fisher - Aquacell

The Benefits

A short course training experience to help understand the future of metal additive manufacturing

Accelerate Innovation

Identify new opportunities for growth and bring innovative parts to market faster when you brainstorm and problem-solve alongside our additive experts.

Reduce Risk

Tap into our advanced technical capabilities to qualify your metal additive parts faster and increase your success rate with additive parts.

Lower Costs

Shorten your time to market and find cost savings wherever you are in the additive process with tailored solutions designed for

Improve part performance and processes

Leverage GE’s team of additive designers, engineers and material scientists to optimize your parts and processes with a systematic approach that goes beyond the part.

Transform your business

Rewrite the rules of manufacturing, optimize your supply chain and open new market opportunities with our unparalleled expertise and proven methodology.

How it Works

What is Metal Additive Manufacturing?

Find out more

With speakers from WSU Launch Pad, Western Parkland City Authority and GE Additive, our audience gained an understanding of what the Program was really about and how it came to be. They met team members delivering the training and asked questions about the sessions.

To understand a bit more about this program, as a starting point click the play button to watch the Information Session.

If you are keen to enrol in the program, click the Express your Interest button and a Launch Pad team member will be in touch shortly.

The NSW Government and Western Parkland City Authority (WPCA) have developed the New Education and Training Model (NETM) in partnership with industry, universities, vocational education and training (VET) providers and government. The NETM will deliver small-scale packages of learning, or micro-credentials, that allow people to build knowledge, skills and experience in a particular subject area aligned to employer needs. For more information on the program, please visit WPCA Website.